Any goods can be moved from one side of the world to the other by sea, air or road. However, there are loads that, due to their volume or dimensions, require special packaging and modes of transport to be able to do so.

In this post we will talk about packaging for large loads, or also known as packaging for large dimensions or packaging for oversized cargo.

What is oversized cargo?

We refer to oversized cargo when, due to its size or tonnage, it cannot be transported in a conventional way, being necessary to resort to specially designed and manufactured solutions to be able to handle it safely.

For example, industrial machinery such as large engines, construction materials such as beams or pipes, as well as all types of packaging for aeronautical, automotive or renewable energy parts such as wind blades or solar panels.

Today, most of the companies in the industrial sector that operate at an international level need a goods protection service for large parts or loads.

Packaging for oversized cargoes – Main considerations

In most cases, it must be approved for export, which means that it has to comply with ISPM-15 certification to avoid any problems at customs.

In addition, it must be reinforced to efficiently support the weight, and if we are talking about bulky goods, it may require a special platform to facilitate its movement.

Phases when designing an oversized package

The first step is to conduct a preliminary study on the needs of the cargo: weight, size or other requirements. From production to delivery, each step is carefully planned and comprehensively oriented.

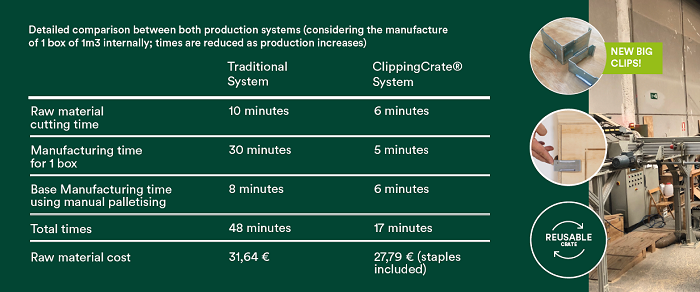

Our technical department develops the best type of protection taking into account factors such as packaging efficiency, use of sustainable materials and space optimization during transport, all from the best technical and economical point of view.

Mechanical considerations

At 360 Eco Packaging we are manufacturers, which allows us to offer ad-hoc packaging according to the needs of our customers.

The designs not only take into account the shape and size of the cargo, but also the use of products approved for storage and lashing in sea containers and trailers.

These are packaging aids, such as heat-sealable plastic and shrink-wrapped plastic, which act as reinforcement against external agents to protect items susceptible to damage by external agents, as well as retention systems to stabilize it, even if it has suffered some kind of impact during the logistics process.

Economic Considerations

We also pay attention to the economic factor. We know that an excess of material and accessories could increase the cost associated with the process. Therefore, the custom design must be economically viable for the customer without compromising cargo safety.

Production and delivery

If necessary, we can carry out packaging of the goods at the customer’s facilities.

Please contact us without any commitment.

![]()