Desiccant salts, also called dehydrating salts, are chemical compounds that absorb moisture and water in very different ratios, depending on the amount of desiccants and their chemical composition, and can regenerate if subjected to a temperature above 150ºC.

There are different types of desiccant, the most common are:

-

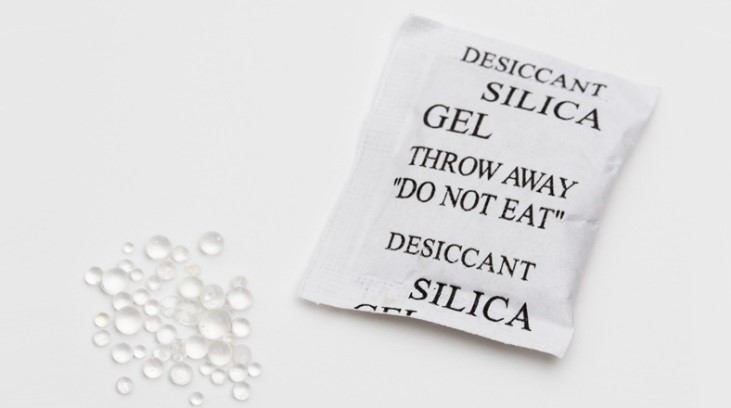

Silica gel

These are small solid pellets of silicon dioxide obtained from sodium silicate. Despite being a chemical compound, it is not toxic or flammable by itself, although one of its components is highly toxic to humans if ingested or in contact with it for a long time, as it could cause silicosis. This is cobalt chloride, which is used to determine the amount of moisture in the gel. In this way, it causes the gel to change color when wet, varying from blue (dry) to pink.

-

Bentonite

Is a very fine-grained (colloidal) clay of the montmorillonite type containing bases and iron. The name derives from a deposit found at Fort Benton, USA. The particle size is less than 0.03% of the average grain size of kaolinite.

-

Calcium chloride

In addition to its use in pharmaceuticals and food, this compound is used as a desiccant, given its moisture-absorbing qualities. It is less common than silica gel, although it does not contain toxic elements and has a higher degree of moisture absorption. The problem is that it is not advisable to use it in spaces that are not hermetically sealed, since it runs the risk of liquefying, with the consequent elimination of its absorption capacity.

Measures

There are four different units for measuring desiccants. The most commonly used due to their standardization are grams, but we also find NFH, DIN units and MIL units.

These would be the equivalences between them, taking as a reference the most used measurements:

We recommend the use of one half kilo bag (16 DIN units) of desiccant or dehydrating salts per cubic meter. As a guideline, we can indicate that for a 20 feet container it is advisable to use 20 bags of 1 kg. These data are estimates since, depending on the cargo to be transported (sensitivity to oxidation and/or corrosion mainly), the proportion of salts should be adjusted to maintain the relative humidity at the established rates.

Packaging

The desiccant can be purchased in bulk or packaged in breathable bags for use in containers or inside packaging.

The bags are made of non-woven textile so that moisture passes through them and can be picked up by the compound. Now, certain desiccant manufacturers have begun using another material called Tyvek, which is used primarily in home and building construction to prevent moisture.

This material is made of high-density polyethylene and nonwoven olefin fiber, so it is highly breathable and its uses are very diverse. Although it looks like paper, we must not forget that it is plastic when it comes to recycling.

As we mentioned at the beginning of this section, desiccant bags are frequently used in containers for shipping goods by sea.

Salt compounds and moisture can cause damage to the goods. For this reason, many containers come with special cables or rings for the placement of desiccants.

In this case, a hook or hooks, usually made of plastic or metal, are added to the bags to attach them to the walls of the container. If the container has no means of hanging the bag, many manufacturers incorporate a special adhesive to attach the bag directly to the inner side walls.

Other remarks

There is a chemical compound called dimethyl fumarate, DMF, which is also used as a desiccant.

Years ago the Finnish doctor Tapio Rantanen discovered that it can cause severe allergic reactions and large skin eczema, even in very small proportions, after the marketing of this product in sofas by a Chinese company, with the aim of preventing the furniture from deteriorating with humidity, resulting in several cases of affected people in several countries around the world, including Spain.

For this reason it is very important to make sure that the desiccant that we are going to use is free of this substance and that it has passed the pertinent controls that indicate it.

It is also common to find in the desiccant packages cards indicating the moisture content of the salts, thus warning if it is necessary to replace the package in case they no longer absorb water vapor.

These cards work by changing color, in such a way that when their blue color disappears and turns to a light pink, as in the case of silica gel, it means that the desiccant salts have already exhausted their absorption capacity.

In conclusion, you will have to choose the type of desiccant that you believe convenient and in the right measure depending on the volume of the load and how it is packed. It is always advisable to use it, since humidity is present everywhere and in certain regions and countries more than in others, but above all it is an indispensable requirement for sea and river transport, combining it with other types of materials for adequate protection.

![]()