Nobody is aware of what they have until they have to move, that is why in this post we will talk about packing for moving. Moving our belongings from one place to another requires good planning, starting with choosing the optimal packaging so that the move is resolved quickly and smoothly.

Like any other type of shipment, each move will require different packaging, depending on the contents to be transported and the mode of transport.

What is the most suitable packing for a move?

The packaging systems for the moving or furniture storage sector share the following characteristics:

- They are light and resistant packaging.

- They are collapsible and can be disassembled and can withstand handling and almost any type of movement.

- They are ergonomic and can be assembled/disassembled very easily, almost without the use of tools.

- Most of them are also reusable, which means cost savings and respect for the environment.

- They have auxiliary packaging systems to ensure the integrity of the load (fastening and lashing, protection and cushioning, control elements).

Types of packaging for moving

No two moves are the same. Moving a house is not the same as moving an office where electronic equipment and components are moved, much less a transoceanic move in a container.

Depending on the volume of material to be transported, wooden, cardboard or cardboard combined with wood packaging solutions can be used.

The most common are:

Cardboard boxes

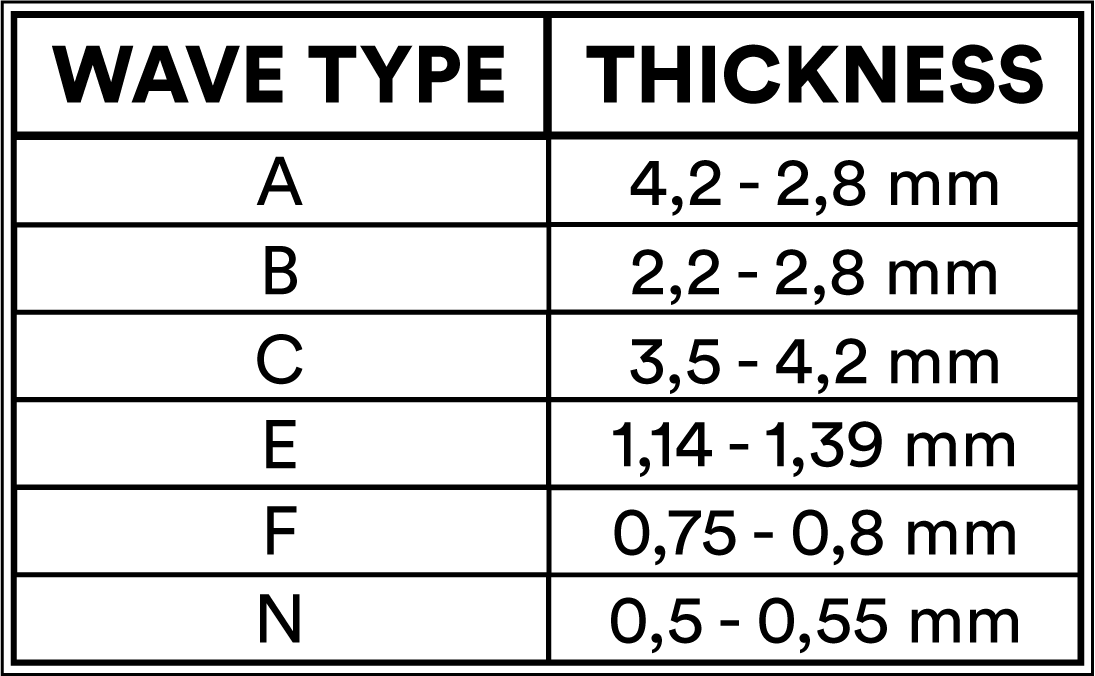

Cardboard boxes are the most common type of packaging used in removals. As is logical, boxes of different sizes are used, depending on the needs. From a weight of 8 kilos upwards, it is advisable to use two-channel cardboard boxes, which offer greater resistance and protection.

Large-volume cardboard boxes, available with flaps or lids, are used to move large furniture and belongings.

Folding wooden boxes

Plywood transport crates with lids are the most commonly used for transoceanic moves. This type of box is made of ISPM15 certified wood, so it is suitable for international shipments.

It is a reusable, stackable and collapsible box. It consists of a lid, a base with support and a very consistent central body. The anchorage of the pieces is by means of metallic tabs, which gives it great resistance.

Fillings to protect the inside of the boxes

Just as important as choosing the most suitable box for a move is to have protection and padding aids to protect the contents inside.

Packing padding products immobilize objects to prevent them from suffering any impact during transportation and protect them from humidity or vibrations so that they arrive at their destination in perfect condition.

An economical solution to protect ceramic pieces, glassware or fragile products, as well as to fill the gaps left in boxes, is cardboard netting.

Cardboard corner protectors and foam profiles are essential to protect the edges on the inside and outside of the boxes.

In international moves, and especially in sea transport, inflatable bags or airbags are used as a complementary system in cargo lashing to fill the gaps in containers and prevent them from moving.

At 360 Eco Packaging we can’t move your things, but we can provide you with the necessary packing material to make your move as safe as possible. Contact us.

![]()