Supply chain security, inflation and sustainability are some of the major challenges that companies face. Among other things, we will discuss the advantages of folding carton packaging.

In the packaging industry, we find ourselves in a market where the demand for sustainable products is growing, the trend is to reduce single-use packaging and to optimize transport and storage costs.

Folding packaging meets all these requirements perfectly. With this post, we begin a series of articles to explain which ones are going to be the most frequently used and what benefits they bring to companies.

Advantages of Foldable Packaging

Quality folding packaging meets all the conditions for use in logistical operations with full guarantees. Their efficiency is proven every day in the storage and transport of goods in any industry.

In addition to strength and safety, they provide a series of advantages that have a direct impact on logistics cost savings:

- Greater space utilization. When not in use, folding packaging takes up less space in the warehouse, which allows for better management.

- Ease of handling. It is ergonomic and facilitates assembly/disassembly, with little need for tools. This cuts work times and minimizes possible damage caused by handling.

In addition, they can be made of cardboard, metal or plastic. In this post we will focus on cardboard folding packaging.

Cardboard Folding Packaging

By its nature, cardboard packaging is considered one of the most efficient on the market. Its popularity is increasing, due to the rise of ecommerce and the ongoing debate on sustainability and ecopackaging.

Cardboard is a natural, resistant and recyclable material, whose versatility makes it the best alternative for creating sustainable and original packaging solutions. Most are also reusable, so they can be used efficiently until the end of their useful life.

Cardboard boxes and pallet boxes

In industrial packaging we use corrugated cardboard, which, unlike other types of cardboard, is the strongest and most durable. Corrugated cardboard boxes in standard sizes or large-volume cardboard boxes can be used for packing and palletizing light and heavy goods, either alone or in combination with protective and cushioning solutions.

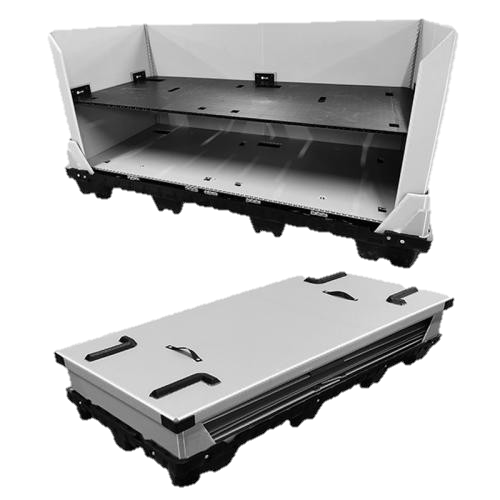

When the type of load requires a folding solution of greater resistance, we can opt for the pallet-box, a mixed packaging. In the pallet-box, the cardboard box is reinforced at the base and sides with wooden slats to facilitate storage and picking.

In 360 Eco Packaging we develop efficient packaging solutions that provide savings along the entire supply chain. Contact us.

![]()