Certifications are key indicators in any activity. Through these accreditations, packaging manufacturers can demonstrate that their products or services comply with the regulations required by transport agreements, and at the same time meet high standards of safety, quality or environmental responsibility. They are, therefore, a guarantee of how we do things.

ISO 9001 certification is one of the most widely implemented standards among companies. In our case, this seal accredits the quality of our processes for the design and manufacture of industrial packaging.

In the packaging field there are other valuable rules and certifications that we highlight below:

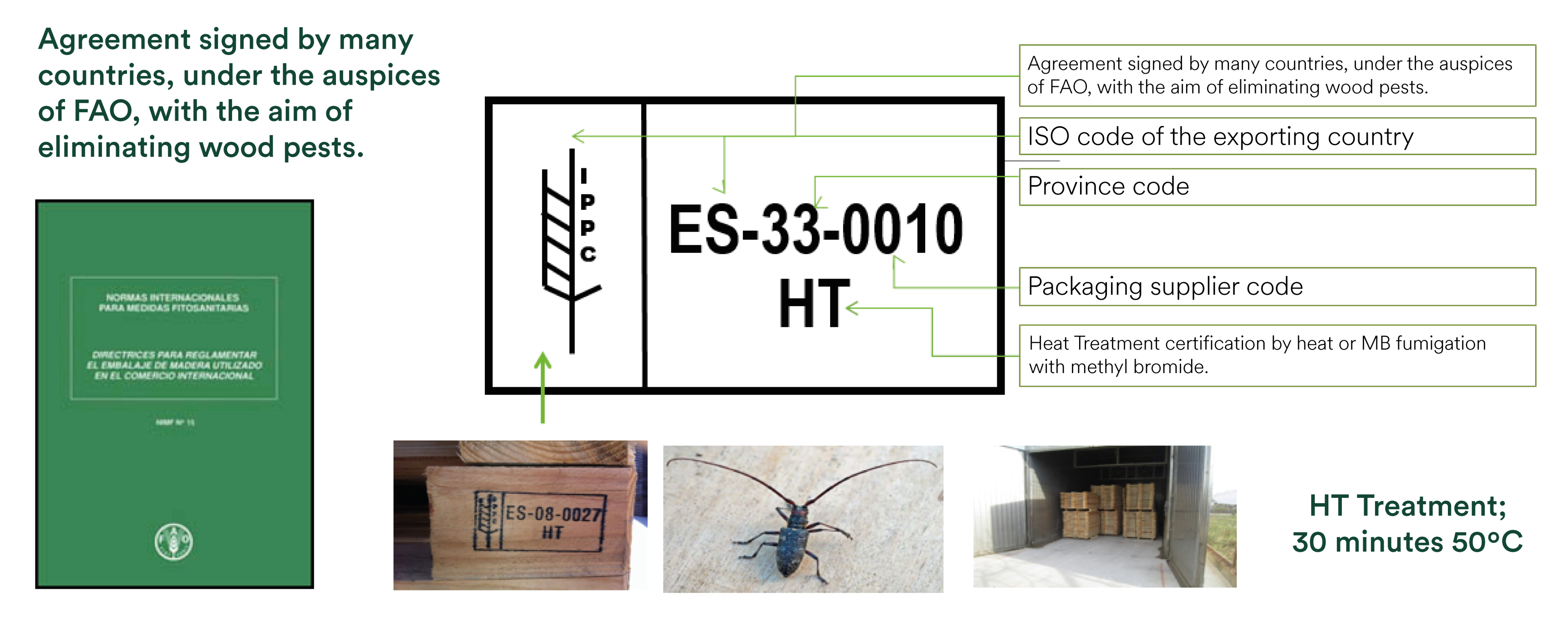

Phytosanitary-certified wood packaging material

The International Standard for Phytosanitary Measures ISPM-15 was created by FAO to regulate wood packaging in international trade in order to reduce the risk of introduction and spread of pests.

The ISPM 15 seal is based on a heat treatment that consists of the wood reaching 56 ºC in its core for at least 30 continuous minutes.

Once the wood has been treated, the mark must be visible on at least two opposite sides of the wood.

The ISPM-15 standard affects packaging made wholly or partially from raw wood, such as pallets, crates, crates, crates, crates, dunnage, pallets, cable drums and reels. Plywood is excluded.

To obtain the ISPM-15 label, it is necessary to be registered in the national system and to pass the required annual audits, through the control of the traceability of the manufactured elements.

The issuance of a certificate will only be necessary if required by the phytosanitary protection agencies of the destination countries.

Certified Dangerous Goods Packaging

Dangerous goods are considered to be solid, liquid or powdered products that represent a risk to the safety and health of people or the environment.

The transport of dangerous goods requires specific approved packaging, with its corresponding certificate in accordance with the regulations of each mode of transport. The regulation par excellence in the transport of dangerous goods by road is the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road).

Compliance is also mandatory:

- Rail RID (Regulations concerning the International Carriage of Dangerous Goods by Rail).

- Air transport IATA (International Air Transport Association).

- Maritime transport IMDG (International Maritime Dangerous Goods Code).

The UN has established a universal system of classification, packaging, marking and labeling of the different dangerous goods valid for all modes of transport.

Dangerous goods packaging can be made of plastic, cardboard or metal, but must always be properly labeled. In addition to the labeling required for each type of goods, according to its classification in the ADR, each package must show a UN number, among other data such as the manufacturer’s code, type of box, password, country and year of manufacture.

The ADR defines packing instructions for each UN number, according to which the physical-chemical specifications that the packaging must meet for a given good will be detailed.

Packaging with PEFC / FSC® certification

Nowadays, it is impossible to talk about quality without taking environmental criteria into account. PEFC and FSC® chain-of-custody certification guarantees good practices along the entire wood value chain.

PEFC-certified pallets, wooden crates and cardboard boxes use raw material from sustainable logging, recycled material or both. Choosing PEFC / FSC® certified packaging means promoting a responsible supply chain, contributing to sustainable forest management and the well-being of forest communities.

These seals are also a competitive advantage in markets that require the supply of environmentally responsible materials.

Use certified packaging suppliers that add value to your logistics.

![]()