Foldable plastic packaging helps to reduce costs and improve the efficiency of the logistics process.

Foldable plastic packaging has qualities that are highly valued in today’s production lines. They are made of stable, lightweight material and are very easy to clean. They are therefore the ideal solution when extreme hygiene is required, as in the case of pharmaceuticals, agricultural products or foodstuffs.

Moreover, they do not require any treatment. They offer a barrier effect against humidity, temperature changes and microorganisms and are suitable for export.

Qualities of foldable plastic packaging

If we add to these properties their ability to fold, we obtain a product that will also help us to optimize warehouse space when not in use.

We cannot ignore the fact that Law 7/2022, of April 8, on waste and contaminated soils for a circular economy (LRSC) penalizes single-use plastic containers and packaging. Returnable and foldable plastic packaging solutions benefit all links in the supply network – producer, distributor and point of sale.

Most commonly used plastic packaging

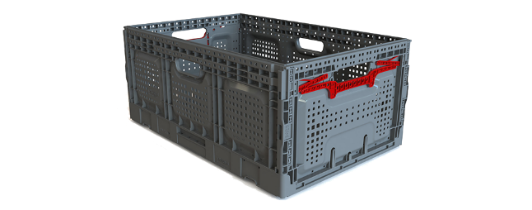

Plastic boxes

At 360 Eco Packaging we are constantly innovating. We have spent years developing solutions that meet the changing needs of the market.

In our product portfolio, we have a range of plastic foldable container boxes that are specifically developed for reuse, stacking and returnability. This type of box is as robust and stable as any other rigid box, but much more versatile, handy and lightweight.

It is made of high-quality recycled plastic and can be recycled again. Its three parts <base, ring and sliding lid> become a plastic container box valid for storage on shelves and / or transport of goods, being suitable for all kinds of roller and chain conveyors.

It is provided with a Velcro system that facilitates its opening and closing. It folds quickly and easily, in just 4 seconds without the use of tools.

Each box can be customized with the company’s corporate colors, bar code labels or RFID elements.

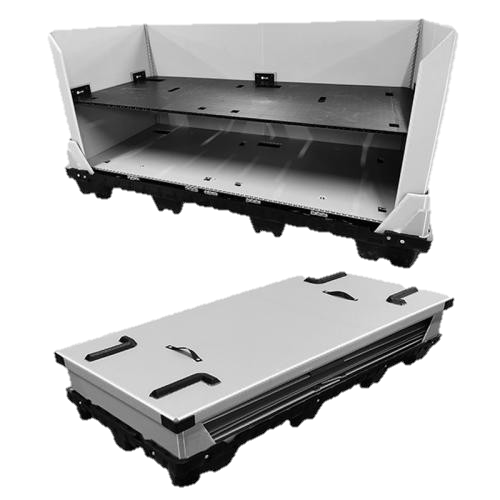

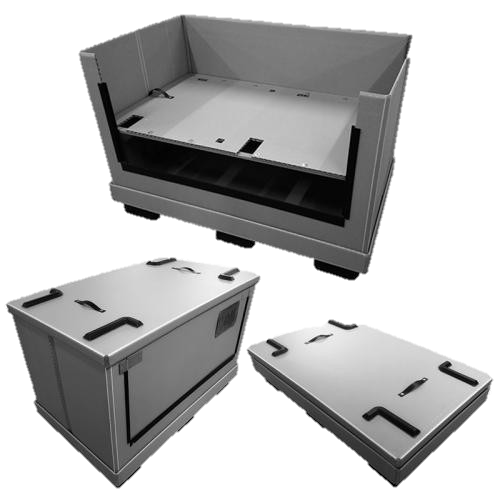

Plastic pallets

Weight is a determining factor in the logistics of any business. The plastic pallet offers optimal stacking resistance. And because of its lightness and durability, it is another foldable packaging with an excellent price/performance ratio.

Advantages of foldable plastic pallets

- They are lightweight.

- They are reusable.

- They have nestable skids.

- Easy to clean.

Check our foldable packaging solutions, and if you have any questions, please contact our team.

We will find the most suitable packaging for your logistic process.

![]()