There are two types of impact detectors: mechanical and electronic.

This time we will focus on mechanical devices, they are the most used and the most affordable due to their simple architecture. They are capable of detecting impacts on one or more axes and there are tared models with different g-force sensitivities.

Therefore, we can classify these detectors as:

Table of Contents

One-dimensional

Mechanical detectors that capture accelerations in only one axis (one direction and two directions).

These detectors are the most commonly used, there are sticker type (with adhesive) that are easily anchored to the packaging to be controlled.

Their placement is generally:

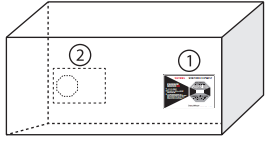

- For a box with a side-to-side proportionality of approximately 1:1

2. For a box with approximate side-to-side ratio > 2:1

3. The heights “h” at which the indicator should be positioned may vary depending on the load, the g-force and the manufacturer.

Most of these indicators are activated by changing color (red) when the maximum set acceleration has been exceeded, it does not show a history of events, for that an electronic detector would be necessary.

Two-dimensional

Mechanical detectors that capture accelerations in two axes (two directions with their two senses).

These detectors are capable of detecting impacts in two directions and even show the direction, sense and modulus of the maximum force to which the load was subjected as shown in the above simulation (provided it is within the operating range of the detector).

Their placement is generally done by means of four screws (per detector) and unlike the one-dimensional ones, their location in the case does not generally interfere in the operation.

There are two main types: magnetic and combined sphere-spring system.

Both are two-dimensional and allow the working accelerations g to be adjusted (depending on their type of construction).

![]()